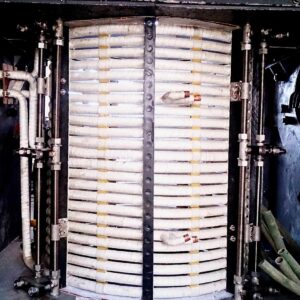

Mehronic Induction Inverter panels are crafted utilizing a series-based technology. This approach offers a multitude of advantages, including simple power and electronic circuits in contrast to parallel technology, a consistent input power factor spanning a wide and accessible power control range, resulting in marked reductions in production costs, maintenance expenditures, repair outlays, and circuit losses. Thanks to its capability to provide uninterrupted power to the cold load, the series-based furnaces demonstrate an average 30% reduction in melting time compared to their parallel technology furnaces.

Mehronic Company is able to design and produce induction inverters with power ranging from 145kW to 15000kW.

Distinguishing Features:

⌘ Full power delivery to the furnace charge from initiation to the culmination of the melting process.

⌘ Automated power control with user-friendly operation.

⌘ Uninterrupted furnace operation and safeguarding of the power circuit against abrupt frequency fluctuations during heavy scrap charging.

⌘ Swift and effective electronic protection systems.

⌘ Effortless troubleshooting of panel components.

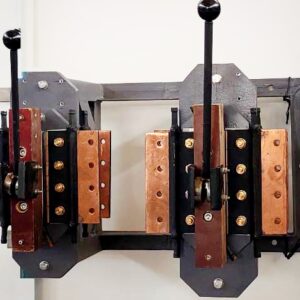

⌘ Elevated efficiency through the utilization of copper bus bars in lieu of water-cooled copper tubes.

⌘ Prolonged lifespan of distilled water facilitated by an enclosed and independent water system for coils and panels.

⌘ Incorporation of thyristor, diode, or IGBT with nominal values up to double the requisite capacity, reinforced by protective circuits leveraging fiber optics.

⌘ Equipped with an advanced, precise ground leak detector capable of assessing and displaying any coil, transformer, or circuit leakage.

⌘ Application of industrial polyurethane paints with anti-scratch properties in a multi-layer coating, enhancing panel longevity.

⌘ Integration of aluminum and stainless steel components to curtail losses and amplify efficiency.

⌘ Utilization of a rectifier with a filter circuit to curtail line harmonics and regulate DC voltage levels.

⌘ Protection of the rectifier segment with specialized, fast semiconductor fuses.

⌘ Inclusion of micro-switches on the panel door to maximize safety precautions.

⌘ Employing high-frequency capacitors with a surplus of reactive power, reinforced by pressure and temperature sensors.

⌘ Control circuit cabin cooling facilitated by fans and water-cooled radiators.

⌘ Display capabilities for furnace power and other performance metrics, encompassing faults, troubleshooting guidance, sintering, or power program according to a specific time graph.

FA

FA

Reviews

There are no reviews yet.