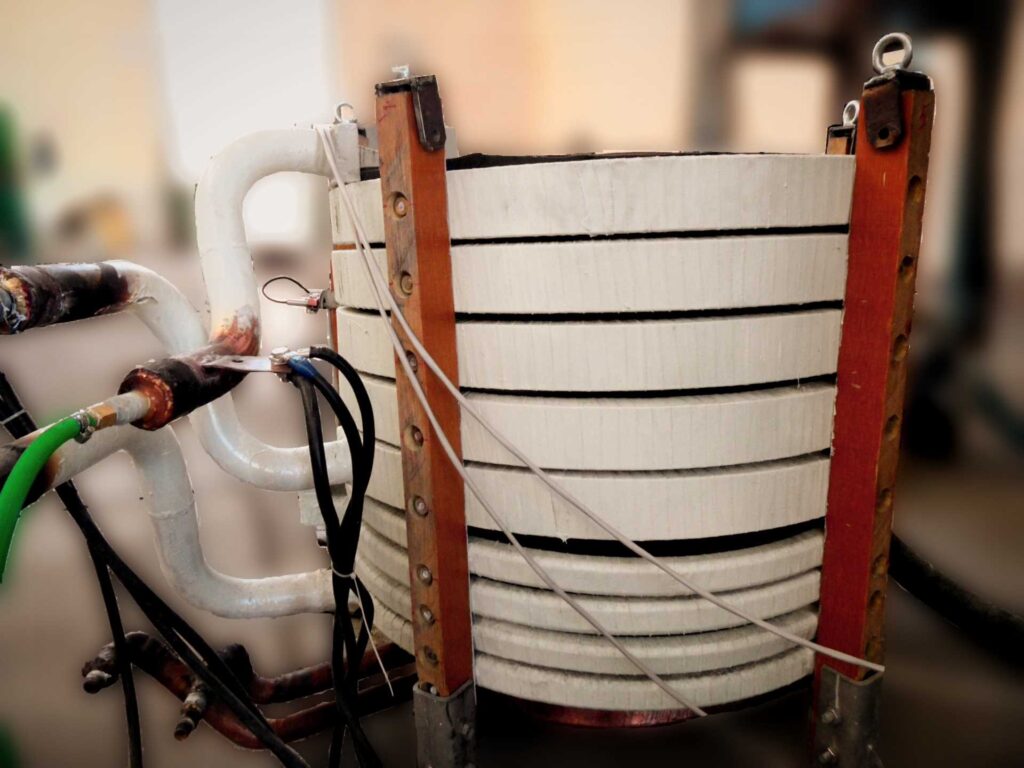

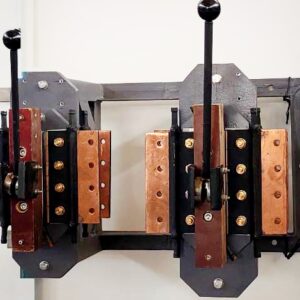

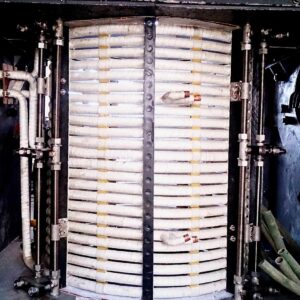

Multi-switch induction inverter is a panel with one inverter that can be switched to multiple coils or zones by fast power electronic switches with high frequency This feature is used in processes that require accurate control of temperature in different zones of the melt or susceptor independently, such as the production processes of jet turbine blades, production of mono crystal silicon, etc.

Mehronic Company’s offering of Multi-Switch Induction Inverter panels spans a power range from 145 to 1500 kW.

Distinguishing Features:

⌘ Capability to implement customized temperature profiles throughout the susceptor

⌘ Ability to introduce temperature bursts directly into any susceptor zone

⌘ Improved efficiency as the system uses only the power needed for induction heating

⌘ Full power delivery to the furnace charge from initiation to the culmination of the melting process

⌘ Automated power control with user-friendly operation

⌘ Uninterrupted furnace operation and safeguarding of the power circuit against abrupt frequency fluctuations during heavy scrap charging

⌘ Swift and effective electronic protection systems

⌘ Effortless troubleshooting of panel components

⌘ Elevated efficiency through the utilization of copper bus bars in lieu of water-cooled copper tubes

⌘ Prolonged lifespan of distilled water facilitated by an enclosed and independent water system for coils and panels

⌘ Incorporation of thyristor, diode, or IGBT with nominal values up to double the requisite capacity, reinforced by protective circuits leveraging fiber optics

⌘ Equipped with an advanced, precise ground leak detector capable of assessing and displaying any coil, transformer, or circuit leakage

⌘ Application of industrial polyurethane paints with anti-scratch properties in a multi-layer coating, enhancing panel longevity

⌘ Integration of aluminum and stainless steel components to curtail losses and amplify efficiency

⌘ Utilization of a rectifier with a filter circuit to curtail line harmonics and regulate DC voltage levels

⌘ Protection of the rectifier segment with specialized, fast semiconductor fuses

⌘ Inclusion of micro-switches on the panel door to maximize safety precautions

⌘ Employing high-frequency capacitors with a surplus of reactive power, reinforced by pressure and temperature sensors

⌘ Control circuit cabin cooling facilitated by fans and water-cooled radiators

⌘ Display capabilities for furnace power and other performance metrics, encompassing faults, troubleshooting guidance, sintering, or power program according to a specific time graph

FA

FA

Reviews

There are no reviews yet.